Ever wondered what the inside of a major league baseball looks like? It's a lot more complicated than it looks.

There are 80,000 Rawlings Official Major League Baseballs (ROMLB) made each year in Costa Rica.

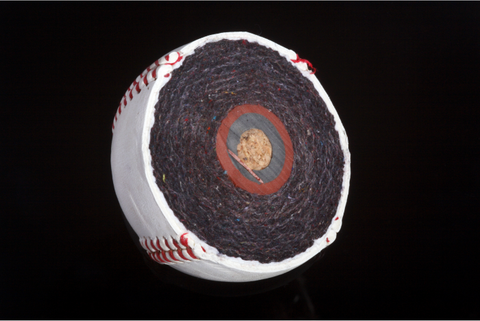

Baseballs contain a cork center called a “pill” that is wrapped in two thin rubber layers. The pill weighs exactly ⅞ of an ounce.

Pills are wrapped with 121 yards of four-ply blue-gray wool, 45 yards of four-ply white wool, and 150 yards of fine white poly-wool blend. This as all done by machine so the yarn remains under constant tension. Once the wool is added the pill becomes a center.

The cowhide used in ROMLB’s is from the U.S. and is inspected for 17 different defects before being used. It gets its white color from the process of alum tanning.

The center of the ball is coated with adhesive, and two pieces of cowhide, shaped like the number eight, are placed on the adhesive.

88 inches of 5/10 red cotton thread is used to stitch the cowhide covers. They are stitched by hand using 108 stitches exactly.

Once stitched, ROMLB’s are machine rolled for 15 seconds to flatten the stitching. Then the Rawlings trademark, MLB logo, and commissioner’s signature are stamped on the balls.

Each ROMLB must weigh between 5.0 and 5.25 ounces as well as meeting diameter requirements between 2.86 – 2.94 inches and circumference specifications between 9-9.25 inches.

Once the baseballs meet the above specifications, a random selection of balls are shot from an air cannon at 88 feet per second. They're aimed at a wall made from northern ash, the same wood used to make baseball bats.

Major League Baseball teams rub their baseballs in a special mud from the Delaware River in New Jersey. The mud gives the ball its off-white appearance and allows pitchers to have a better grip and more control over the ball.